What Comes with Your New CNC Machine

Welcome to the product page for the Arc 1 CNC plasma table, the ultimate solution for precision cutting of various materials, including steel, aluminum, and more. This powerful machine is designed to provide you with unmatched performance, accuracy, and speed, making it the perfect addition to any metalworking shop or industrial facility.

The Arc 1 CNC plasma table features a robust construction that ensures maximum stability and durability. The machine is built with high-quality materials that can withstand heavy use and extreme conditions, ensuring reliable performance and longevity. Its advanced cutting system utilizes a powerful CNC controller, which allows you to program complex cutting patterns with ease and accuracy.

Key Features:

Precision Cutting - The Arc 1 CNC plasma table offers precise cutting of materials with up to 0.002” accuracy. This means you can produce intricate cuts with ease and achieve the highest level of precision in your work.

Powerful Cutting Capacity - With a cutting capacity of up to 1.5 inches (dependent on power source), the Arc 1 CNC plasma table can handle even the thickest and toughest materials with ease. This makes it a versatile machine that can handle a wide range of cutting applications.

Advanced CNC Controller - The machine's advanced CNC controller allows you to program complex cutting patterns and shapes with ease. You can customize the cutting speed, torch height, and other settings to achieve the perfect cut every time.

User-Friendly Interface - The machine features a user-friendly interface that makes it easy to operate, even for novice users. The interface is intuitive and allows you to control the machine with precision and accuracy.

Low Maintenance - The Arc 1 CNC plasma table requires minimal maintenance, thanks to its robust construction and high-quality components. This makes it a reliable and cost-effective investment that will provide you with many years of trouble-free operation.

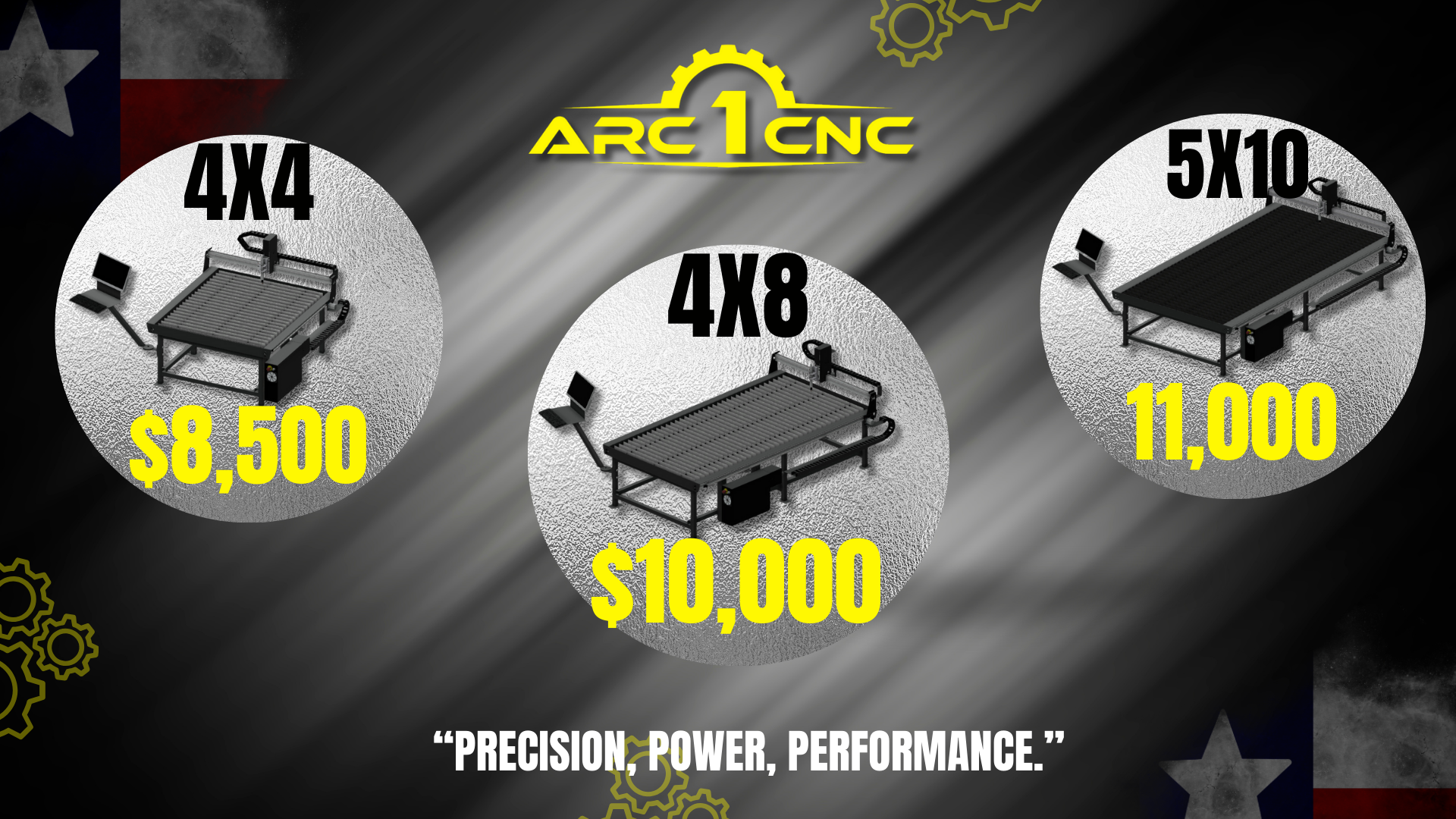

Affordable - The Arc 1 CNC plasma table is an affordable solution that offers exceptional performance and quality. It is a cost-effective alternative to more expensive machines on the market, without compromising on features or quality.

Controller & Monitor

- Our system comes with a Dell Desktop Computer and Stand for Safe storage and operation of your plasma cutting process.

- Loaded with Intel I3 Duo Core Processor 4 Gigabytes DDR4 SDRAM Memory

- 500 Gigabyte Hard Drive with (4) - USB Ports (2 front/2 rear)

- 1 - RJ-45 Ethernet port and 1- HDMI Display Port, adaptor for HDMI to VGA.

- 19" LED Computer Monitor, a USB Keyboard, and Optical Mouse

- Loaded with Windows 10 Professional, 64-bit OS fully interfaced and tested with Customer's Machine before you turn it on

Software

Path-Pro Control Software

- Control system comes loaded on computer with Path-Pro

- Allows direct import of DXF, BMP, JPG, and HPGL files

- Visual Gcode display on your monitor to track cutting in progress

- Customizable M-Codes and Macros using vbscript

HyperTherm ProNest® LT Nesting CAD/CAM software

- Drawing and Nesting program designed for lightindustrial, mechanized cutting and production environments, intuitive and easy to use

- Integrated 2D CAD program to create and edit CAD files Variable Shape Parts

- Vast library to develop common parts from templates and artwork to use and modify to your specific dimensions

- Material database (with grade and gauge) Data information

- Custom remnant creation (define irregular shapes for nesting)

- Access to Hypertherm’s tech service engineers is included at no additional charge

SignTorch Super Bundle

- 14,500 Vector Art Designs

- 5 Vector Formats: AI,CMX,EPS,SVG & DXF Clip Art for CNC CAD CAM